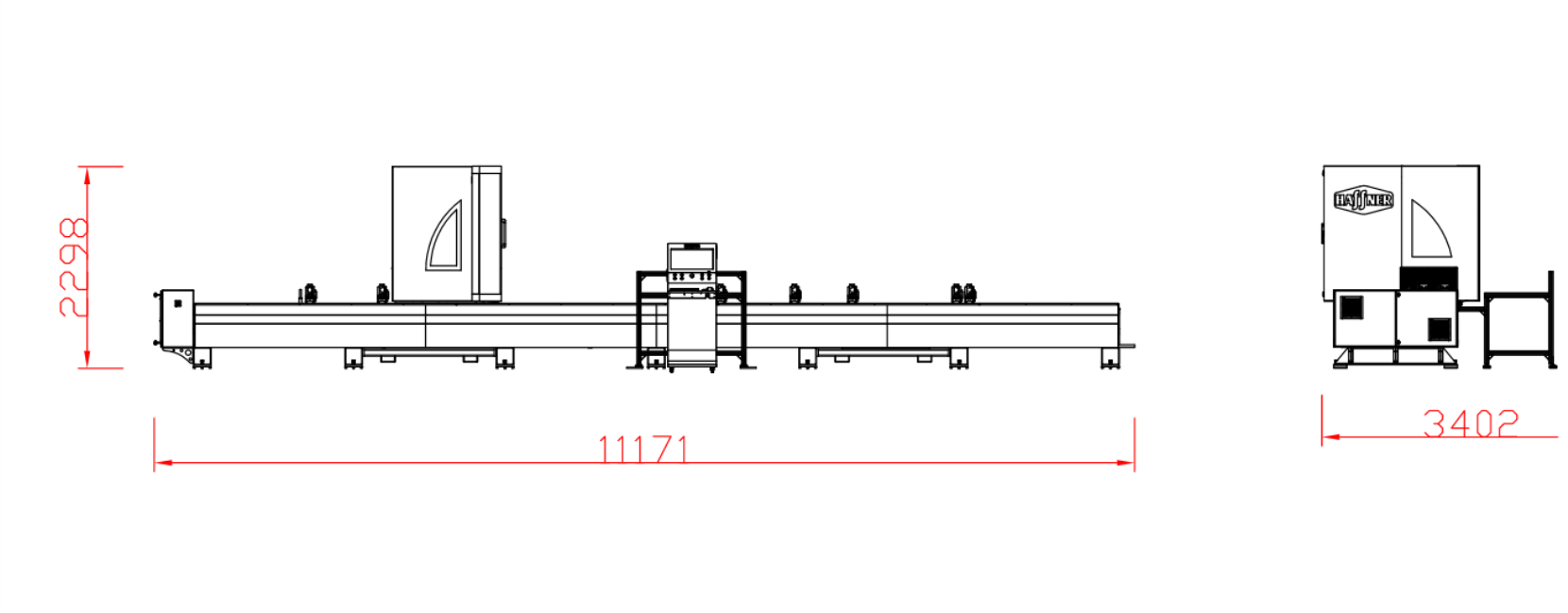

MAC 440440 Profile Processing Center

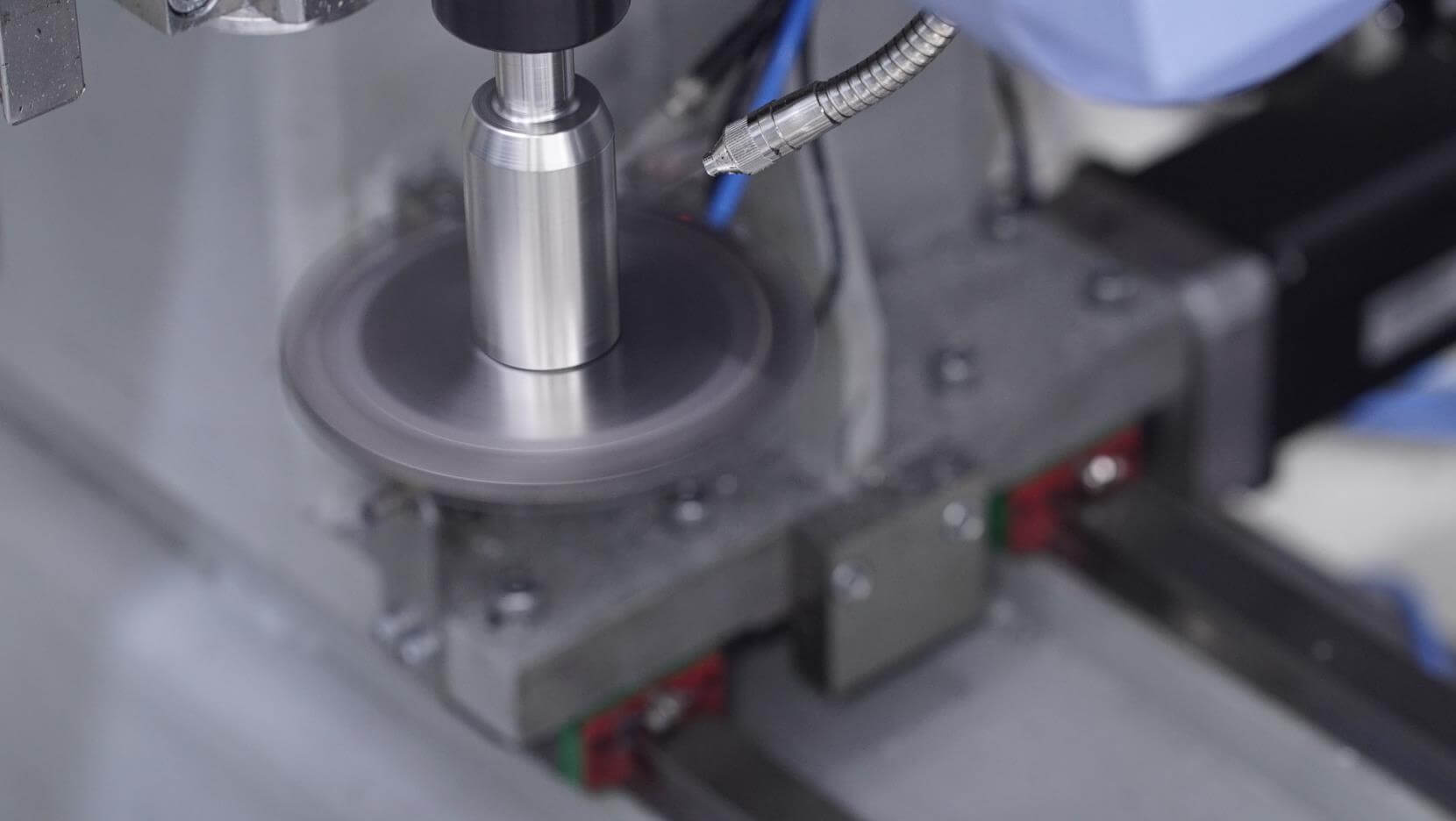

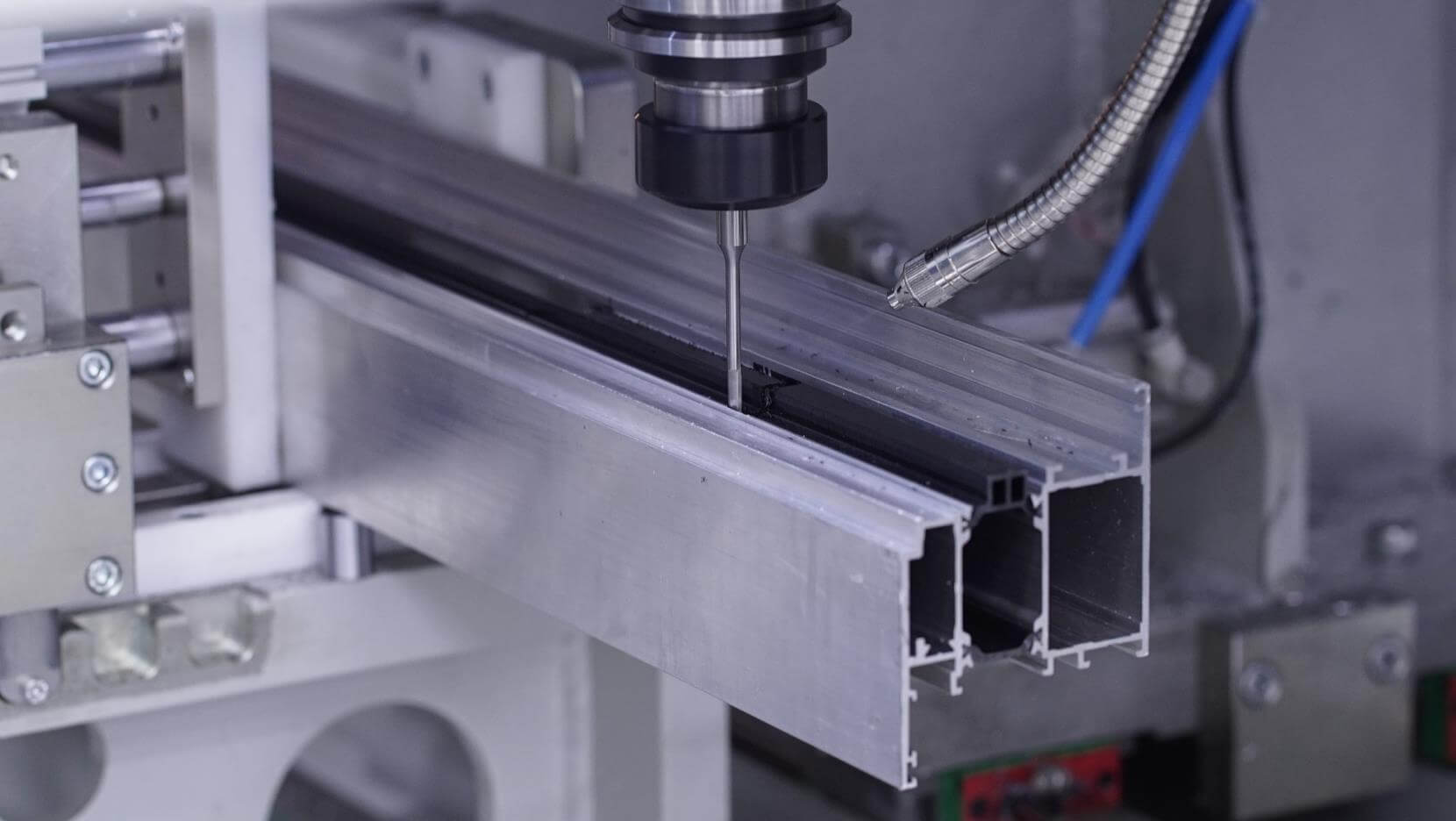

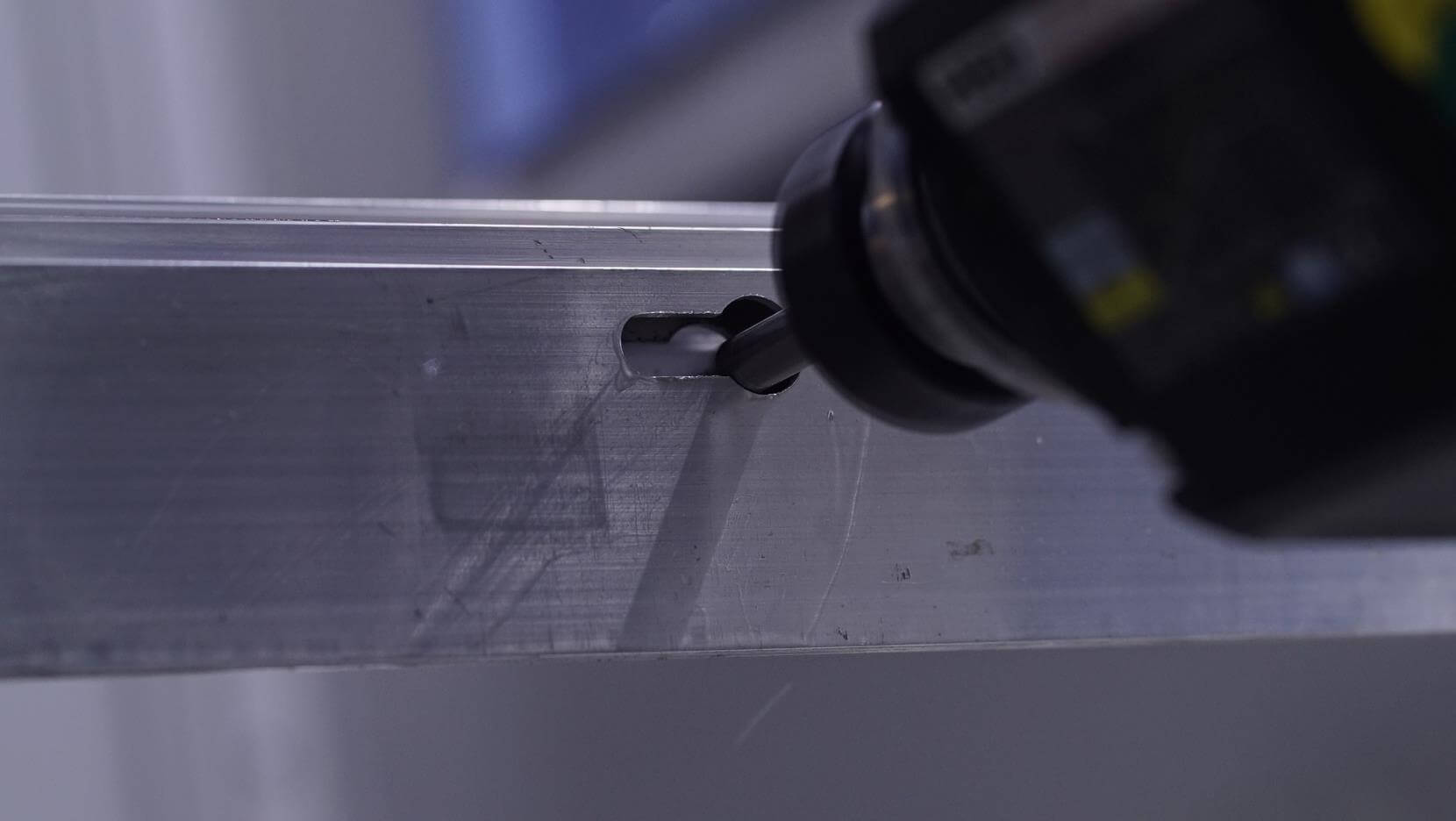

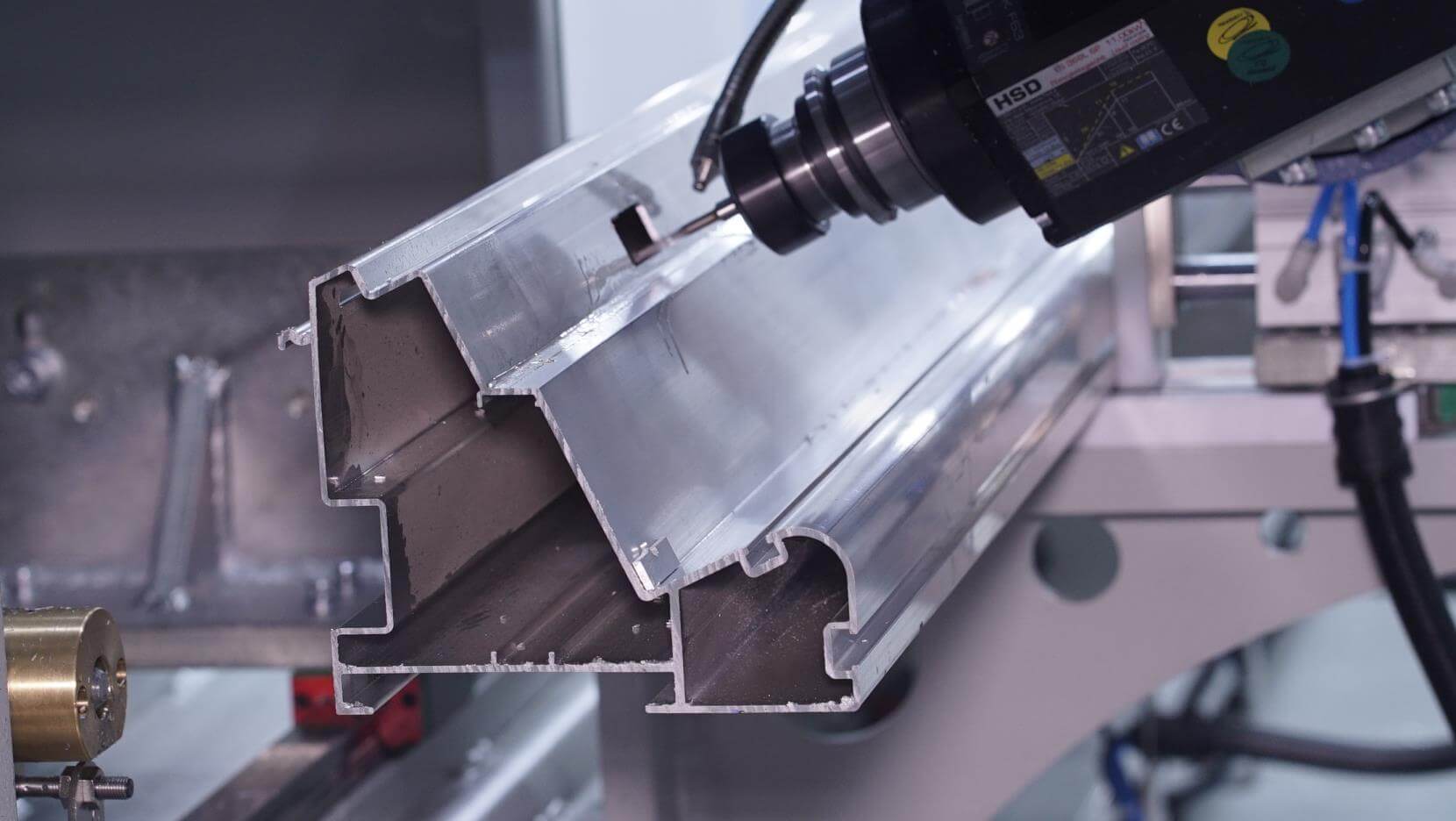

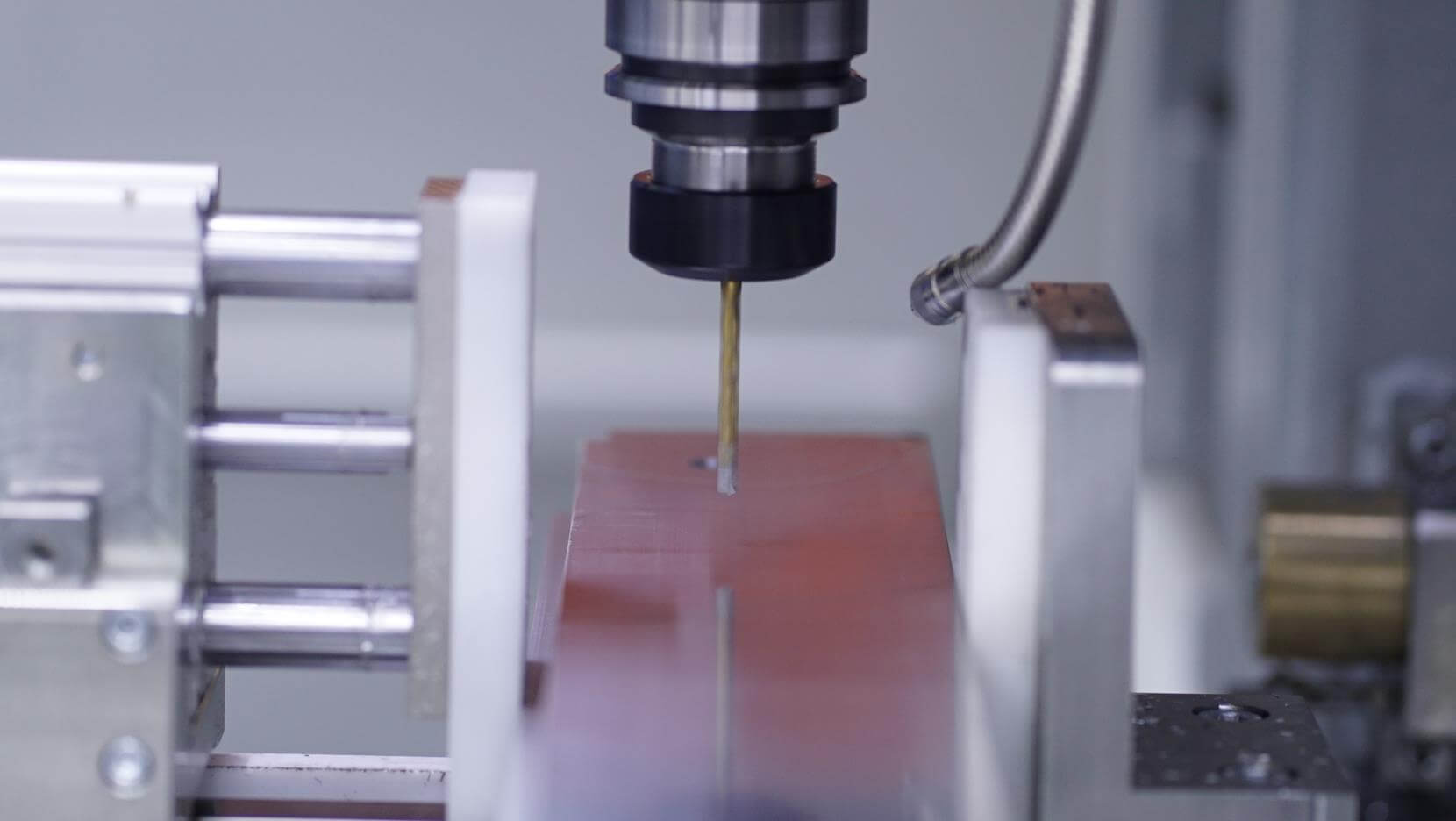

The MAC 440 Profile Processing Center is designed to perform standard operations on profiles such as milling, drilling, notching and marking, flowdrill and tapping, with computer control. In this way, the operations performed on more than one cutting machine are collected in a single machine, ensuring production speed and quality standardization, at the same time, labor cost is reduced.The MAC 440 Profile Processing Center performs all operations on the profile with 0.1 mm precision with its ability to interpolate on the profile to be processed in 4 axes.

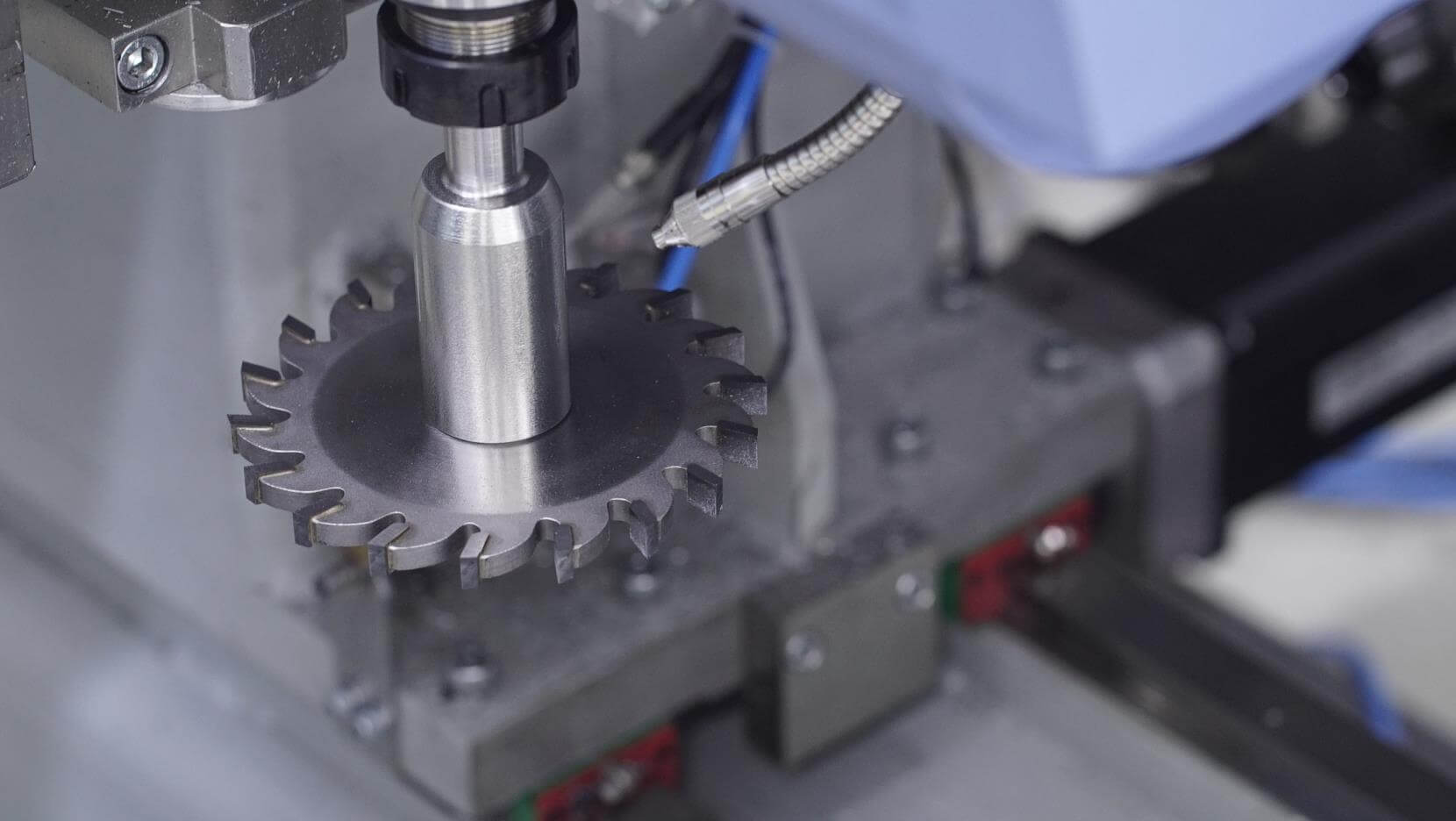

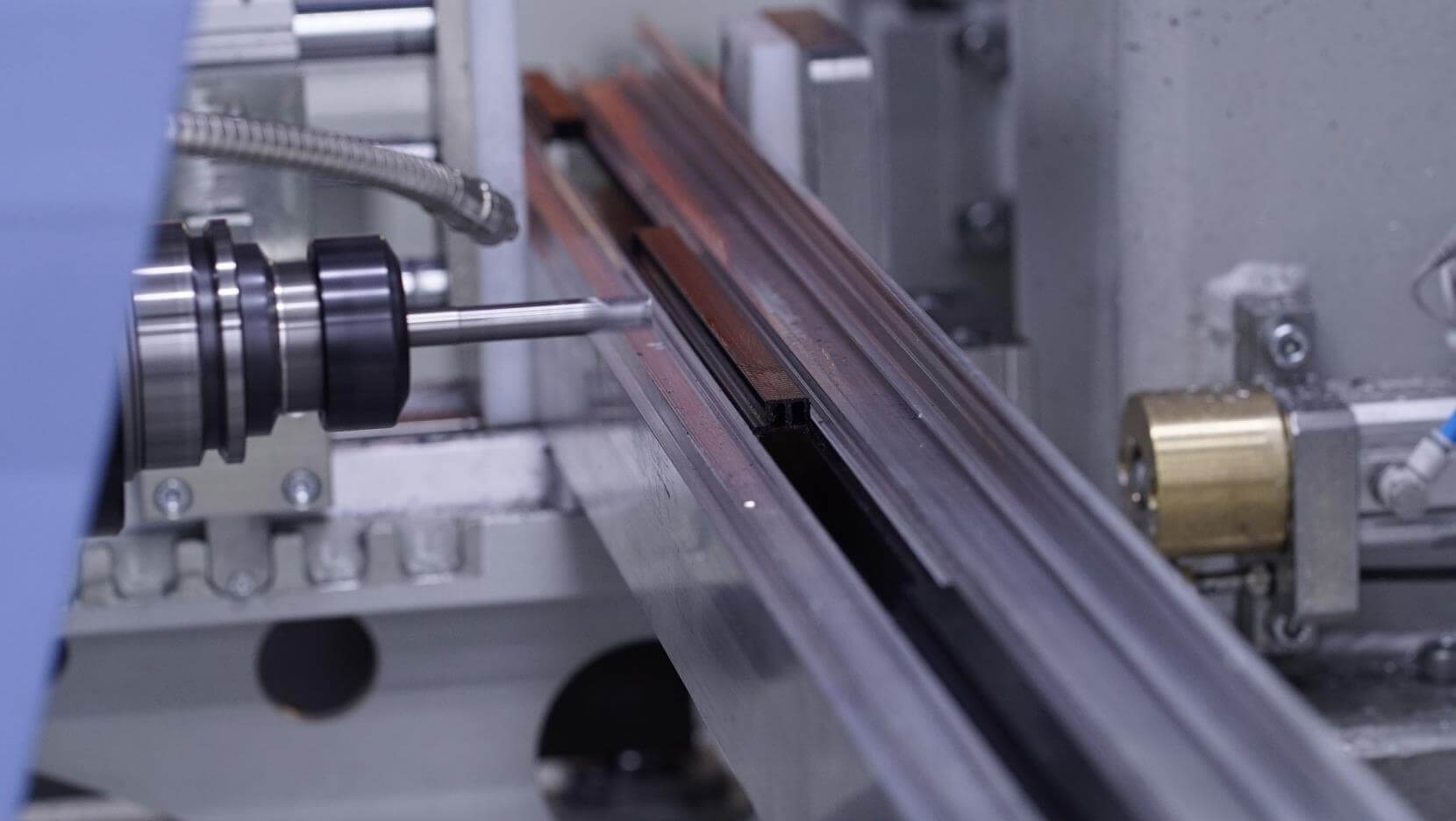

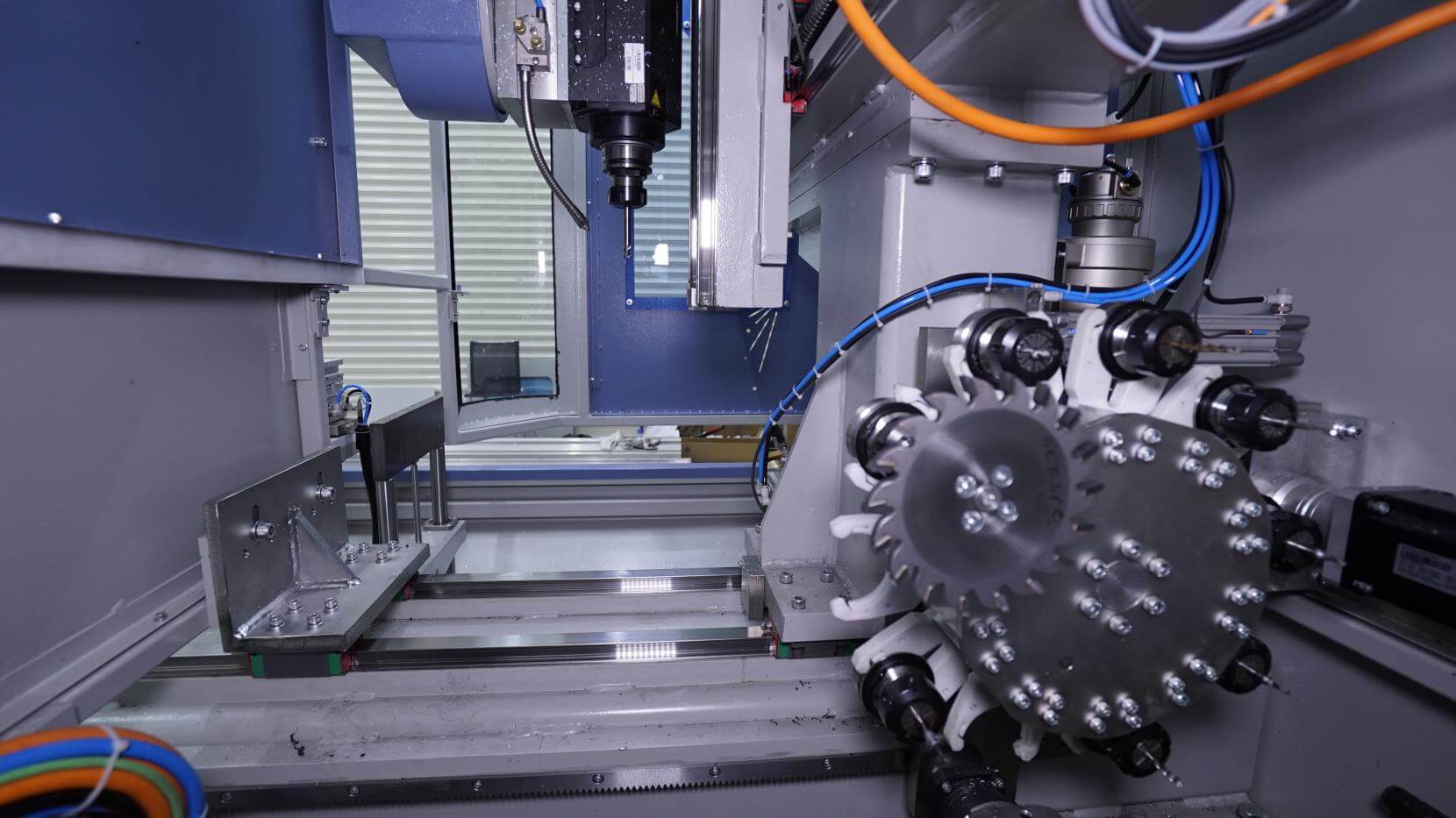

The operation can be performed at all angles between + 120 ° and -120 ° continuously in the A axis. Thanks to the wide profile processing capacity it is capable of processing profiles with different designs and sizes. With a water-cooled spindle (optionally 11 kW) with a motor power of 8 kW, it provides the opportunity to process profiles up to 8500 mm in 4 axes. The process head advancing with a speed of 120 m / min in the X-axis provides minimum time loss and maximum production capacity when switching between milling operations. Total of 10 tools including the cutting blade can be placed, the tool change is made automatically by the machine according to the process to be performed. Because the Tool Magazine is placed inside the machining head, MAC 440 can perform the tool change while it takes position for the next operation.

Therefore, tool change time losses are minimized compared to fixed tool machines. Thanks to the profile supports on the left and middle, MAC 440 can be used as two stations, thus allowing profile processing in one station while profile loading / unloading at the other station, thus increasing the production capacity up to 30%. MAC 440 Profile Machining Center has a 15.6 ”high performance industrial PC with Windows 10 operating system, working without fan between 0 ° C - 55 ° C, placed on an ergonomic unit independent from the machine and offered with a user-friendly interface developed by Haffner. It has an ergonomic hand station integrated with the industrial PC, allowing the operator to intervene manually and at the same time controlling the speed of the milling and cutting operations. Profiles to be milled and cut can be viewed in 3D on the computer screen and operations can be adjusted manually on the screen. It can work in integration with facade, door and window software belonging to different brands and optionally, it has the ability to connect with SolidWorks for industrial applications. Apart from these connections, data can be transferred to the machine using the USB port. With 10 horizontal pneumatic compression pistons, it fixes the profile in the best way and provides milling operations with minimum tolerance.

According to the operations on the profile, the horizontal clamping pistons are automatically moved in the X axis, preventing the stops required for manual adjustment during the process and allowing fast operation. Mc 440VMachining Center is supported with remote connection and provides problem detection and solution by connecting to the entire automation system. The operating system automatically cleans the unnecessary processes of the last session at every startup and shutdown of the machine, ensuring maximum security measures against virus infection and user errors. Daily backup is done automatically to the internal backup unit. The system provides the opportunity to control the production daily, weekly, monthly and yearly with the shift control system. There is a central lubrication system that facilitates machine maintenance. The MAC 440 Profile Processing Center is produced with an optional 11kW water-cooled spindle at the order stage, allowing it to be used for processing larger and thicker profiles.