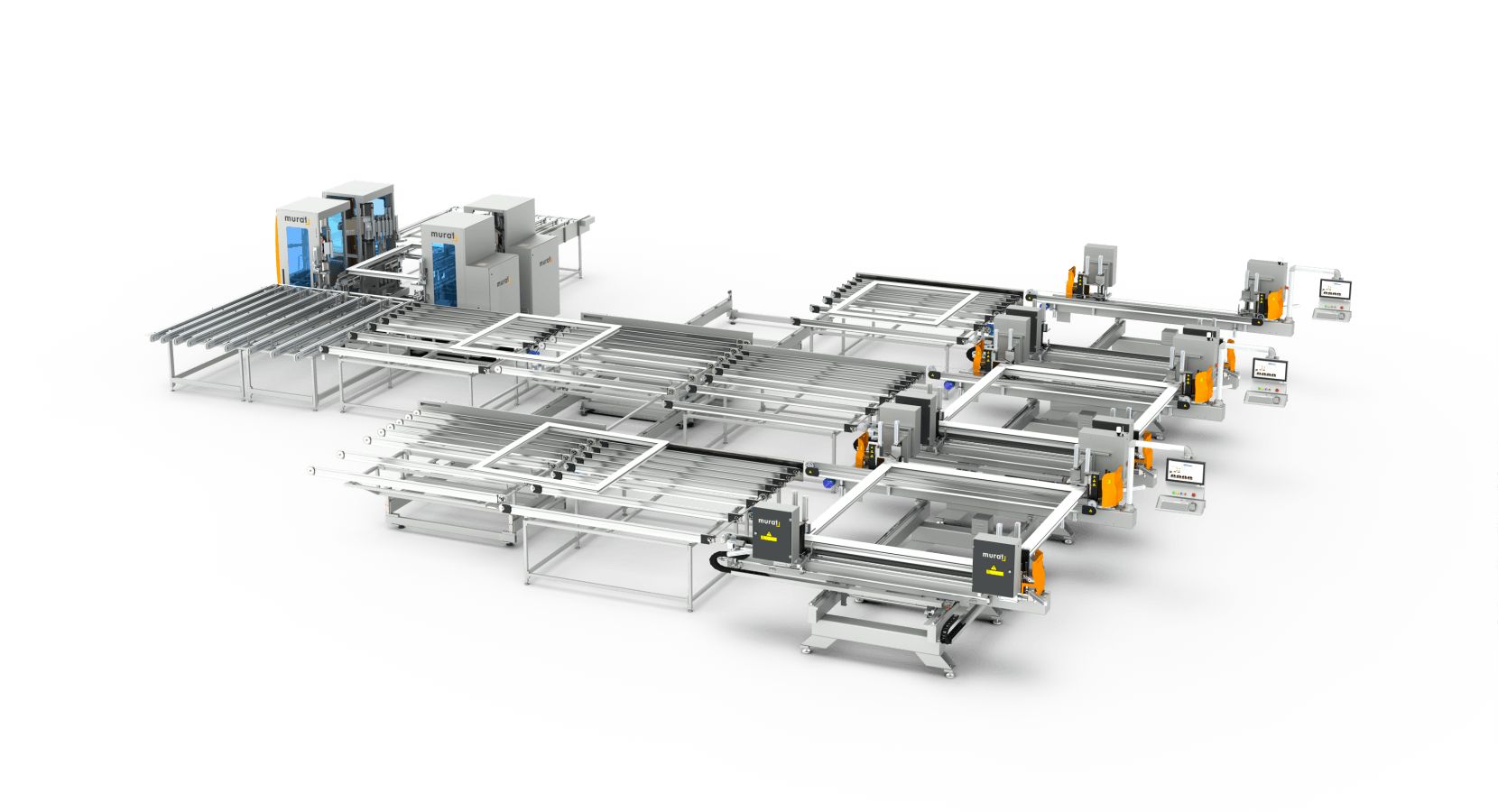

Single Line 4Automation Production Line

Thanks to the SET 4 Automation Production Line, it provides the opportunity to produce at high capacity and maximum efficiency without loss of labor in the process from the source to the end of the cleaning line. It automatically performs welding and cleaning operations by sending data to the Four Corner Welding machine with the help of barcode or network connection of PVC frames of different types and sizes. It enables high capacity production by combining 2 or 3 four corner welding machines and four corner cleaning machines.

Thanks to the integrated automation line, it needs minimum space for high capacity production. It allows the frames to be transferred from the welding machine to the end of the CNC Corner Cleaning machine with moving and stationary frame transfer stations. All stages of the process, from loading the profile to the cleaning of the four corners, are controlled by the computer. All rails and moving transfer systems are specially coated against corrosion.

CK 188 Buffer Cooling Station/ CK 187

Before transferring the boiled profiles from the welding machine to the turning station for cleaning the corners, it keeps them waiting for the necessary cooling. Computer controlled triple handle drilling and espagnolette canal opening operations are performed during frame cooling (CK 188). The cooling time is controlled by the computer on the welding machine side.

CK 190 Ordering Conveyor

It takes the frames coming out of the welding machines from the holding stations and automatically transports them to the transfer station of the cleaning line.

CK 196 Window Seperating Conveyor

It takes the frames to be cleaned one by one to the four corner cleaning machine. Bottom moving carriers and robot clamping system make the processes faster. Thanks to the horizontal and vertical conveyor belt system, the frames coming from the transfer station are stably.

CK195 Off Loading Conveyor

The four corners of the frame are cleaned to the point where the operator will take the frame. Barcode Reader (AK 002), Gasket Printing System (AK 032), 0.2 mm and 1.2 mm automatic welding range selection (AK 052) are optionally available. Barcode Reader (AK 002), Seal Printing System (AK 032), 0.2 mm and 1.2 mm automatic welding range selection (AK 052) are optionally available.