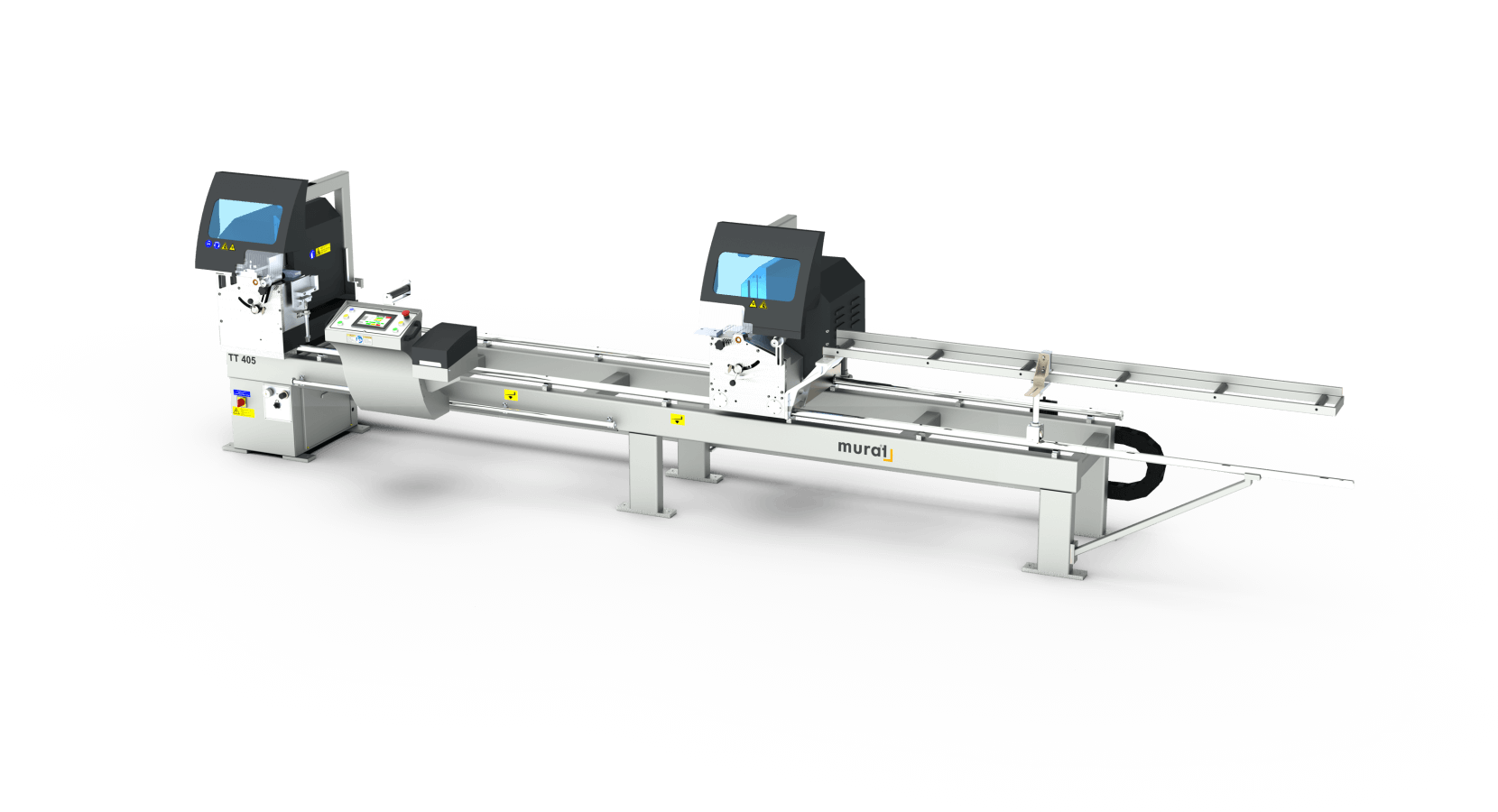

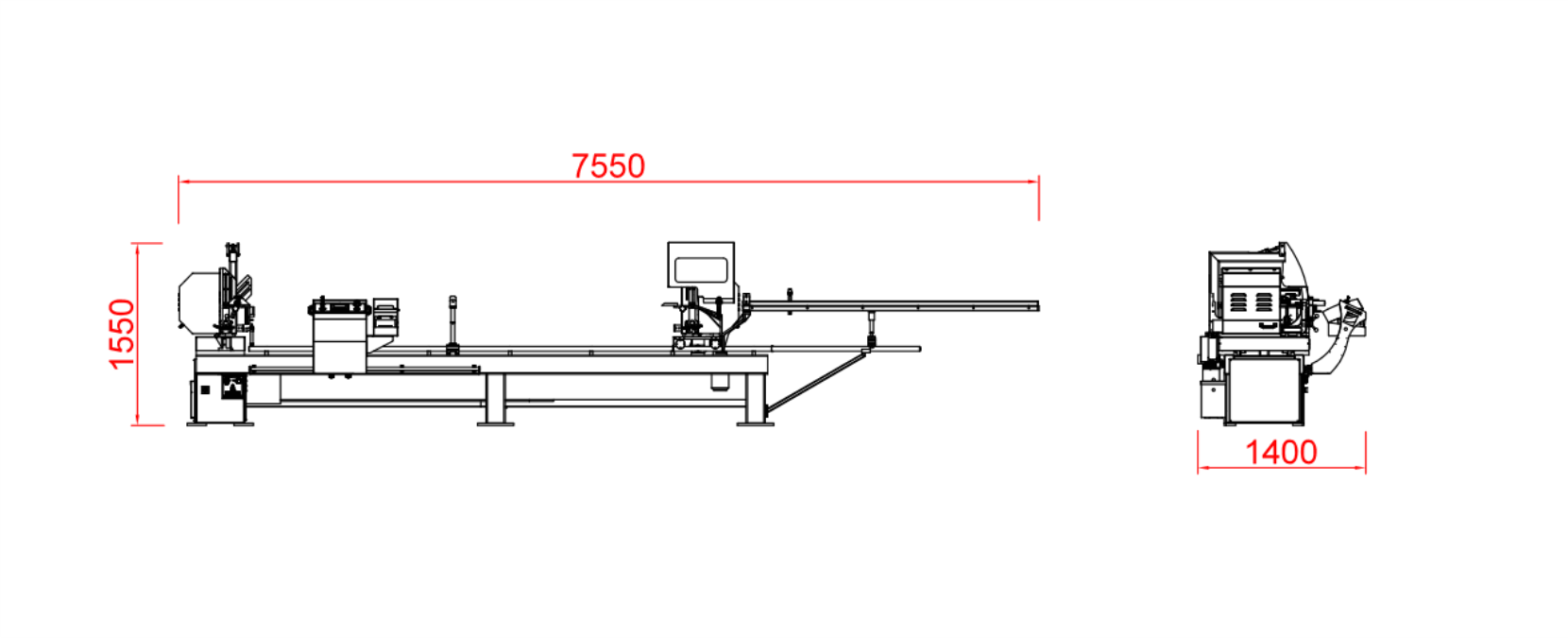

TT 405Double Head Cutting Saw (Ø:450 mm)

TT 405 Double Head Cutting Saw, with strong construction for length and angle accuracy, cuts aluminyum and PVC profiles with adjustable saw output speed. It can cut standard 4200 mm profile and automatic tilt movement for saws in 45 ° and 90 ° is possible. Intermediate angles can be easily adjusted manually. The moving head automatically positions itself with the PLC control system with touch panel. Piece number, length dimensions, angular positions and quantities can be programmed on the control panel. It offers data transfer via remote network connection or USB. The control system can skip and then continue with cutting order. The profile support conveyor on the moving head keeps the working material in balance, ergonomic design and ease of use. With its ergonomic design, automatically closing protective covers increase work and worker safety. It fixes the profile in the best way with its horizontal and vertical pneumatic clamps.

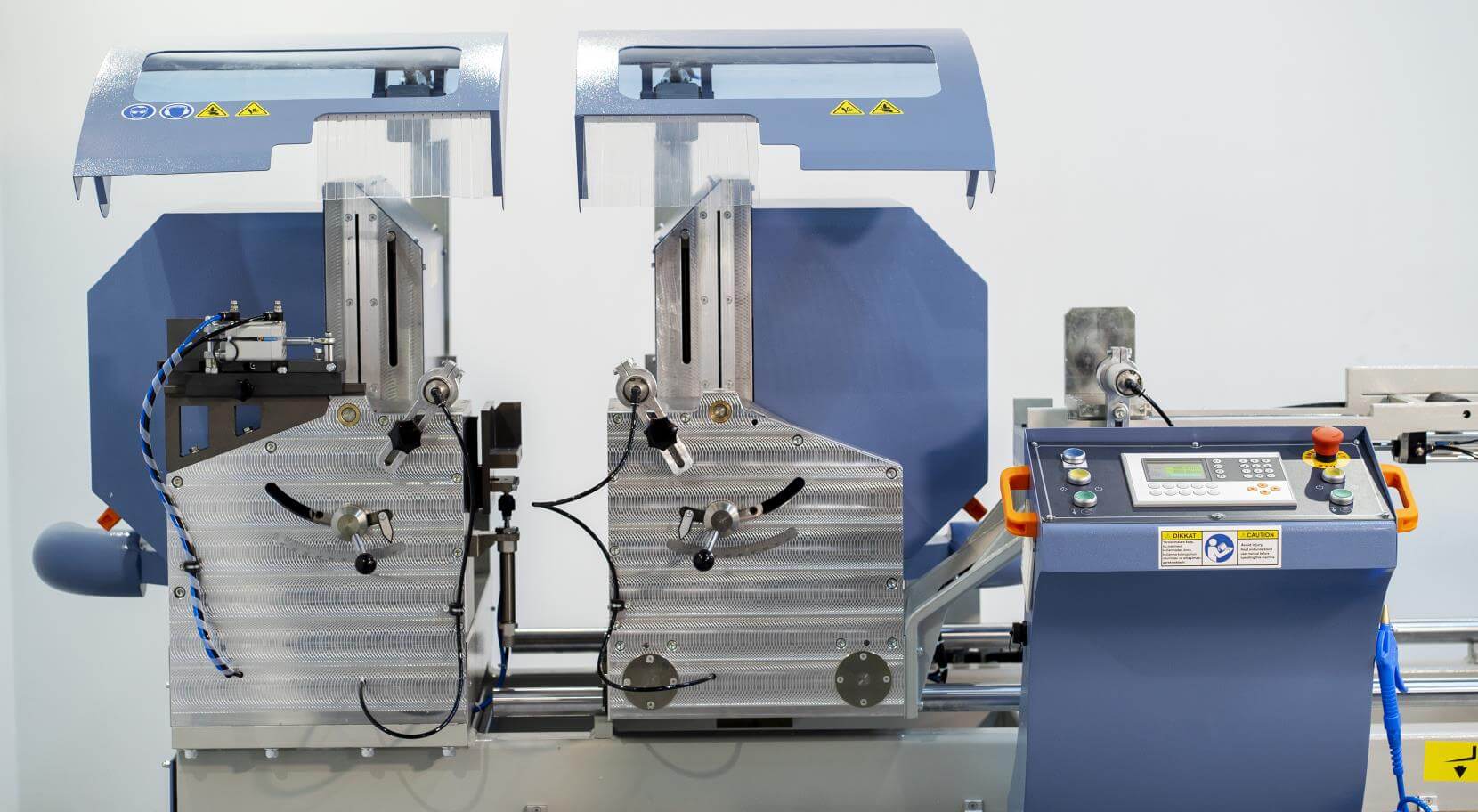

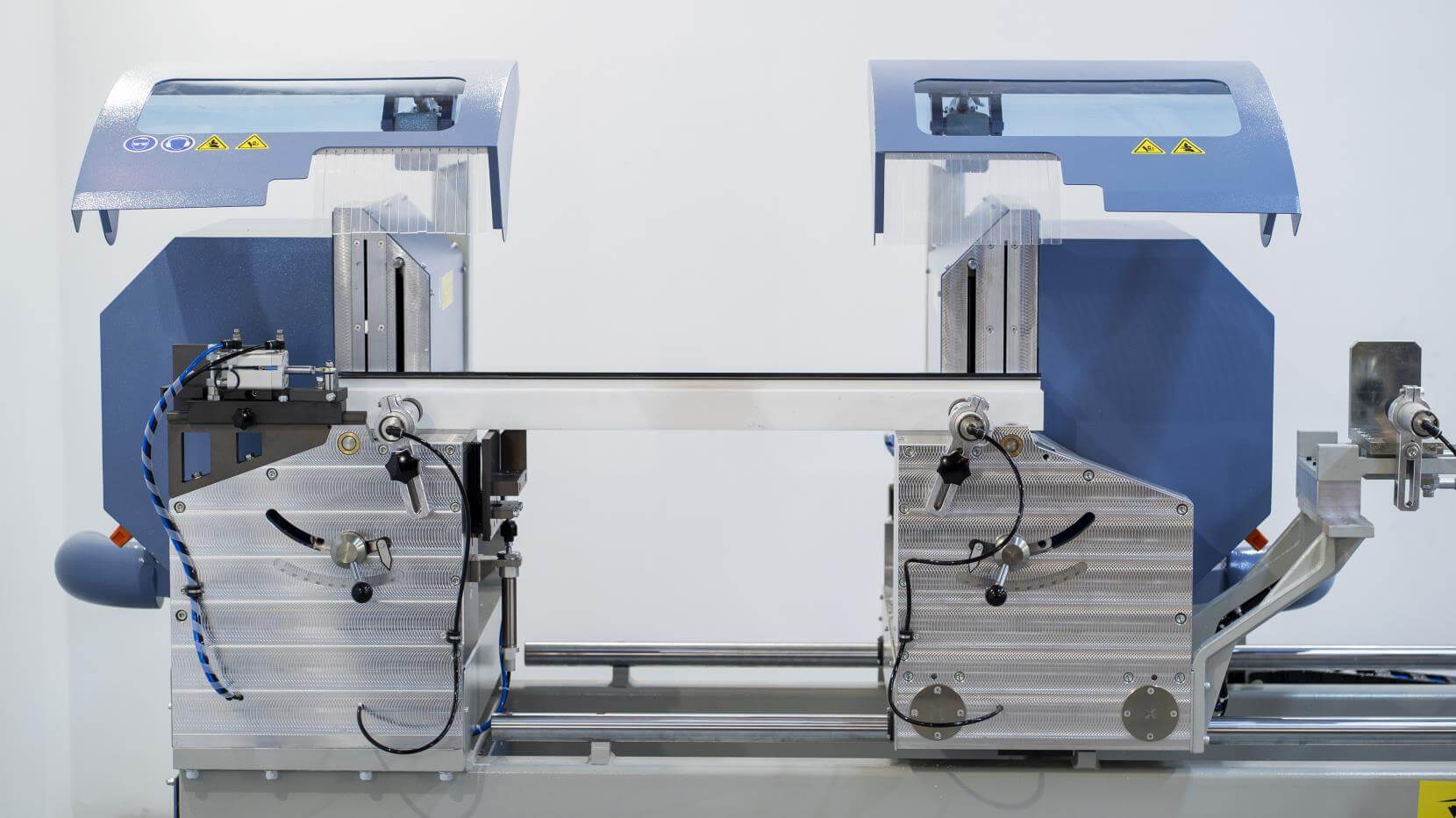

TT 405 Double Head Cutting Machine can easily cut Aluminum and PVC profiles with 2 saws in 450 mm diameter and working with the “oncoming” principle. Parts up to 4200 mm can be cut automatically. Cutting quality, length and angle precision are provided by its specially designed structure with a strong construction. TT 405 Double Head Cutting Machine provides automatic positioning for 45 ° and 90 ° angles with a single button cutting with inward recline position. All other intermediate angles can be easily adjusted manually by the operator. While the cutting head on the left side is fixed in TT 405 Double Head Cutting Machine, the cutting head on the right side is automatically positioned according to the length of the profile to be cut. The movable head is automatically moved to the desired position, based on the size entered by the operator on the touch screen and fixed pneumatically.

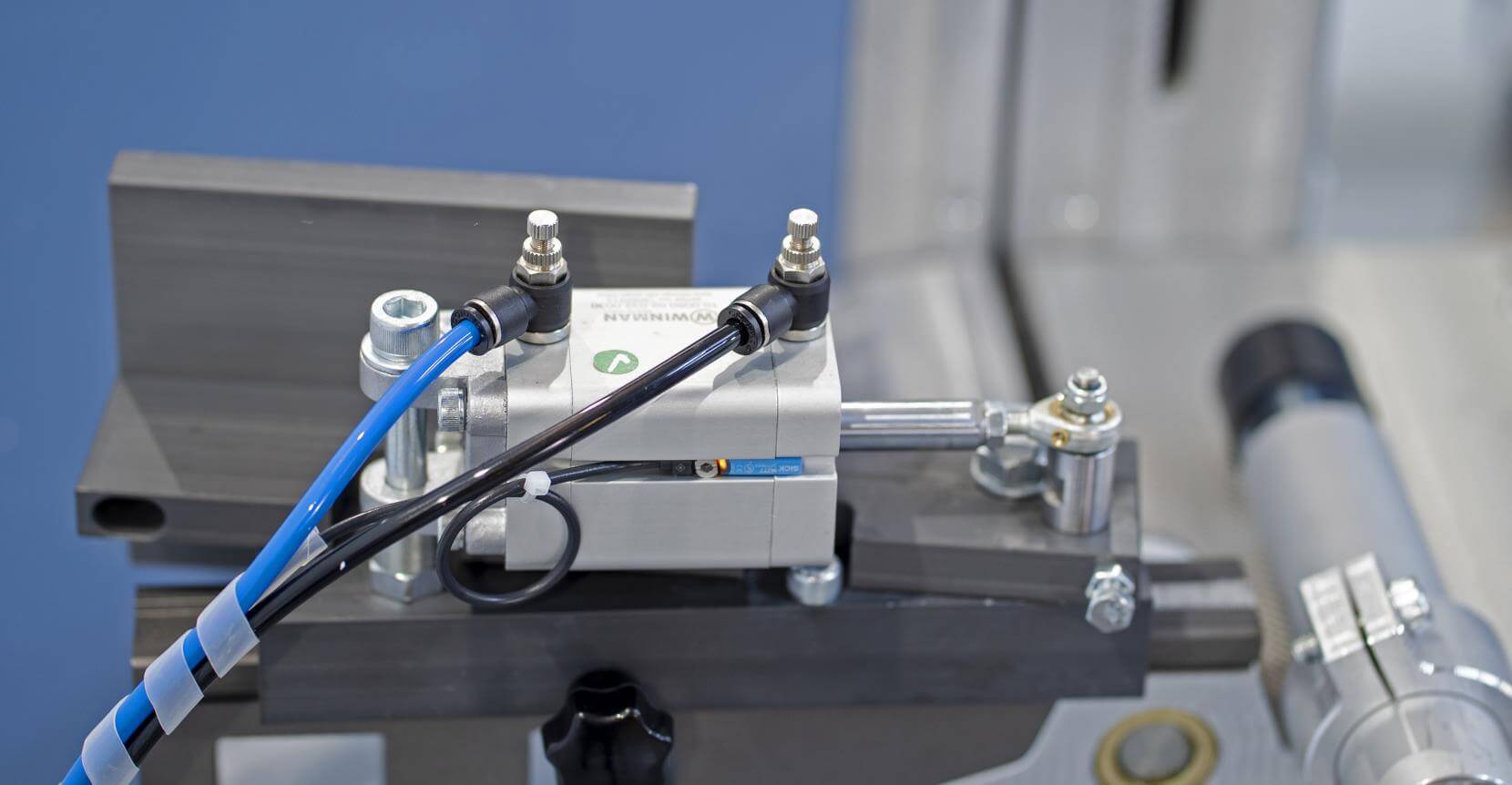

The profile support conveyor on the moving head keeps the profile to be cut in balance. The number, length dimensions, angles and numbers of the piece to be cut can be entered manually on the touch screen, and can also be prepared in advance, sent to the cutting machine simultaneously by USB or remote connection. In case cutting is interrupted or switched between cutting lists, the machine can automatically continue cutting from where it left off. In TT 405 Double Head Cutting Machine, the profile is fixed in the best way with both vertical and horizontal pneumatic compression pistons and the cutting result is obtained with minimum tolerance. Thanks to the horizontal pneumatic clamping pistons, more than one profile can be fixed at the same time within the saw diameter. Upon customer demand, it can be manufactured as single phase 220V or three phase 380V during production. Thanks to the "Hydropneumatic Saw Feeding System" designed for cutting aluminum profiles, the profiles can be cut in the most precise way with minimum tolerance in desired dimensions. Automatic lubrication of the saw during the cutting process ensures the protection and longer life of the saw.

Thanks to the control panel designed in accordance with the CE regulation, which enforces two-hand use, it is ensured that work accidents that may occur during cutting are prevented and a maximum safe working environment is created during cutting. By adding an optional "Barcode Printer System" (AK 003) to the TT 405 Double Head Cutting Machine, all cut profiles can be followed in the factory. "Automatic Corner Chock Cutting System" (AH 025) can be added as an option so that aluminum wedge profiles can be cut with the same precision and standard thickness. An optional "Dust Extraction Unit" (ES 024) can be added to the machine in order to minimize the profile chips generated after cutting and to facilitate cleaning